+86 13794640490 info@sinobake.net

| Availability: | |

|---|---|

| Quantity: | |

HJ800/1000/1200/1500/1800

SINOBAKE

8438100090

Product Description

Composition of Soft and Hard Biscuit Production Line (for reference)

SINOBAKE Fully Auto Biscuit Making Machine Soft and Hard Biscuit Production Line Biscuit Forming Machine (Capacity can reach 150~5000kgs/h,according to the oven length and biscuit type)

Production Process:

Mixing---Feeding---Sheeting---Forming---Baking---Cooling---Packing

1.Horizontal Dough Mixer/Vertical Dough Mixer | 2.Tiliting Machine |

| 3.Metal Detector | 4.Feeding conveyor |

| 5.Laminator | 6.Two Roll Sheeter |

| 7.Dough breaking machine | 8.Dough Scrap Recycle System |

| 9.Rotary Moulder | 10.Rotary Cutter |

| 11.Transition Conveyor | 12. Oven belt drive |

| 13.Enter Oven Machine | 14.Oven(Gas,Electric and diesel oven can be provided) Length is depends on the capacity. |

| 15.Out Of Oven Machine | 16.Cooling conveyor |

| 17. Oil Sprayer | 18.Star wheel stacker |

| 19.PLC Control System |

1. Horizontal dough mixer

1. Horizontal dough mixer

2.Vertical dough mixer

3.Metal detector

4.Dough feeding conveyor

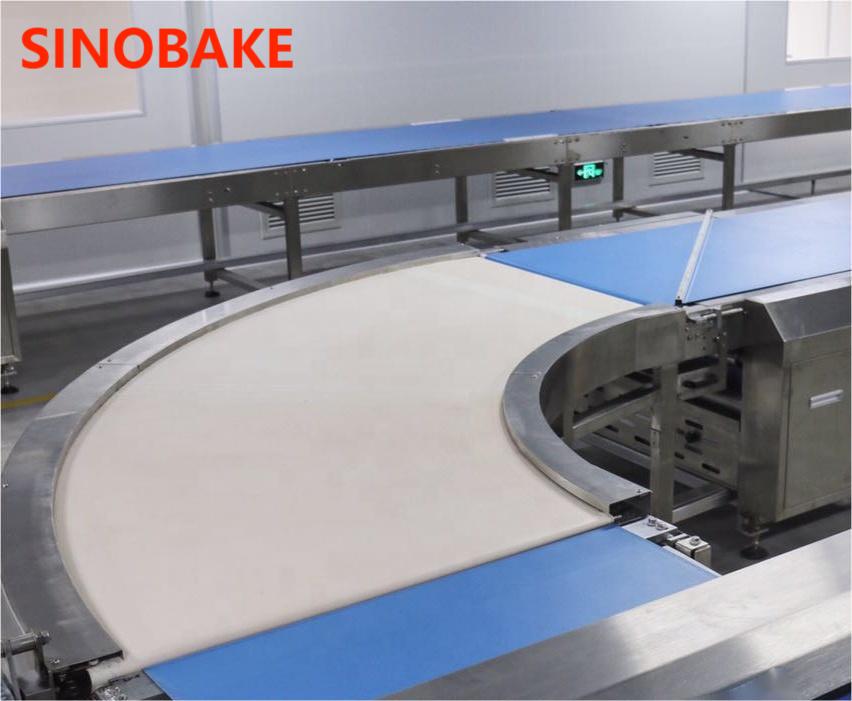

5.Laminator

6.Two roll sheeter

7.Soft dough kibbler

8.Dough Scrap Recycle System

9.Rotary moulder

10.Rotary cutter

11.Transition conveyor

12.Oven belt driver

13.Enterr oven machine

14. Oven

15.Out of oven machine

16.Cooling Conveyor

17.Oil sprayer

18.Star wheel stacker

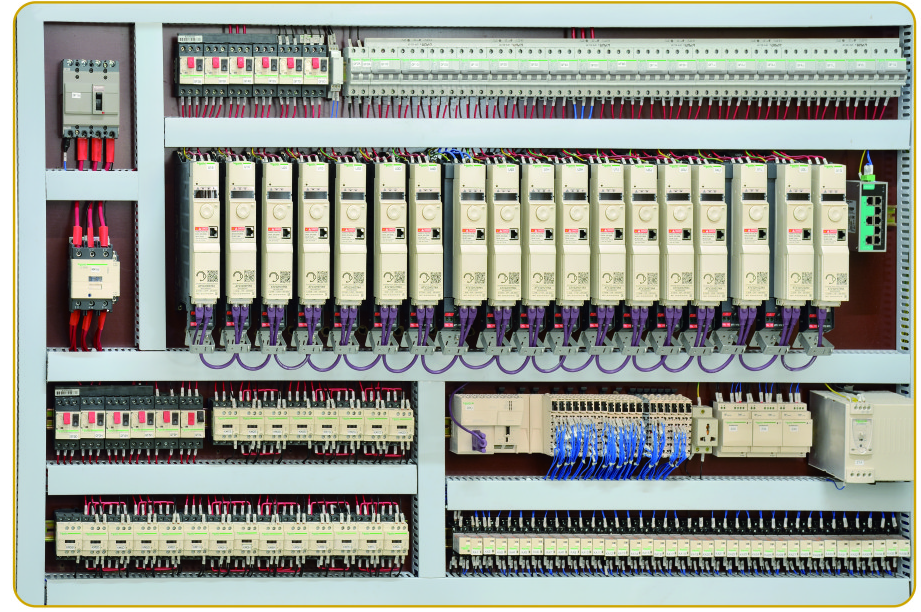

19.PLC control system

MIXING SECTION(Choose according to capacity)

1. Vertical dough mixer

Used to mixing the hard dough

2. Horizontal dough mixer

Used to mixing the soft or hard dough

FEEDING SECTION

3. Tilting machine

Used to easy to transport the dough to the dough feeding system

4. Metal detector

Used to detect if the dough contains any metal

5. Automatic Dough feeding system

Used to automatic conveying the dough to the next machine

FORMING SECTION

6. Laminator

For Hard biscuit production, sheeting and overlapping the dough, increase layered of biscuit.

7. Relaxing machine(Optional)

Used to adjust the tension of dough. Avoid out of shape

8. Gauge roll

Used for half-sheeting and sheeting dough for hard biscuit production line.

9. Rotary cutter

This machine is the forming equipment of hard biscuit , the dough will be cutting to hello panda biscuit shape or others shapes by rotary cutter.

10. Separating machine

Designed for separating the unbaked biscuit and the scrap.

11. Dough scrap return machine

Designed for scrap recycling when producing hard biscuit, also used for feeding of soft biscuit dough.

12. Rotary moulder

Used to soft biscuit forming

13. Egg sprayer(Optional)

Used to spray the egg to the biscuit, improve the taste

14. Salt and sugar sprinkler(Optional)

Used to sprinkles salt and sugar or other granular material equally on the surface of the biscuits to improve the taste.

BAKING SECTION

15. Enter oven machine

Designed for sending the unbaked biscuit into the baking oven

16. Oven drive belt and tension system

Mainly provide motive power to oven belt,drive the mesh belt,the mesh belt can be tensioned manually, pneumatic offset adjustment,the belt has brush cleaning device.

17. Tunnel Oven 60m (Gas/Electric/Diesel oil for optional)

Used to baking biscuit

18. Out oven machine

It is used for conveying baked biscuit out of oven smoothly.

SORTING SECTION

19. 90/180 degree turning machine(Optional)

It makes a 90°/180°turn after biscuit come out of the oven, so that the plant can be used properly.

20. Oil sprayer

It sprays atomized oil with high speed on the up and down surface of biscuits, it can improve the color, smell, and taste of biscuits, the excessive oil can be recycled through filter, and reuse through conveyor.

21. Cooling conveyor

It is used for cooling and conveying the biscuits in normal condition. Have Z type or straight type.

22. Star wheel stacker

It is used for sorting the biscuits before packaging, to make the packaging work easy.

23. Packing console

It is used for checking the quality of biscuits before packaging.

24. PLC System

Used for automatic control and remote monitoring of biscuit production line

Contact us for more information !!