+86 13794640490 info@sinobake.net

| Availability: | |

|---|---|

| Quantity: | |

HJ1200

SINOBAKE

8438100090

Product Description

Production Description

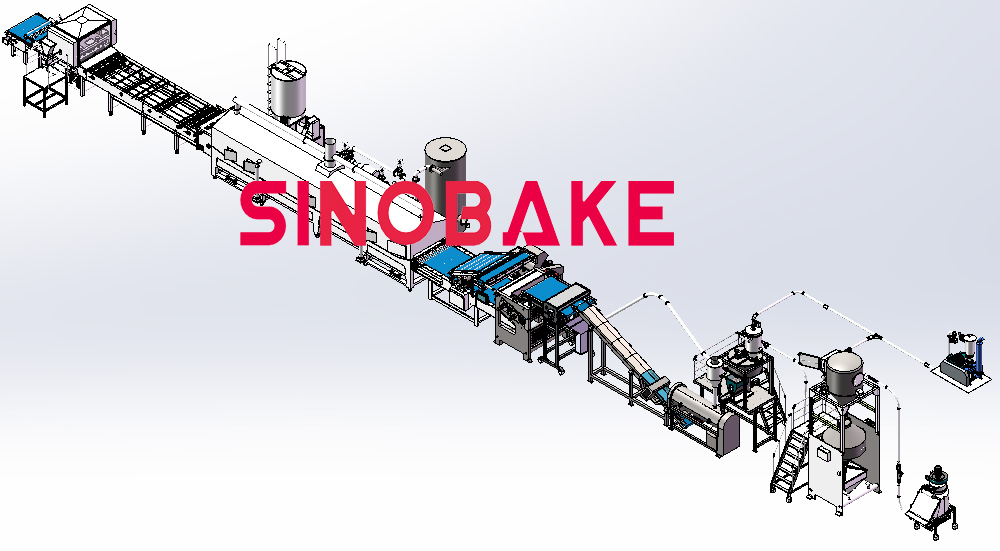

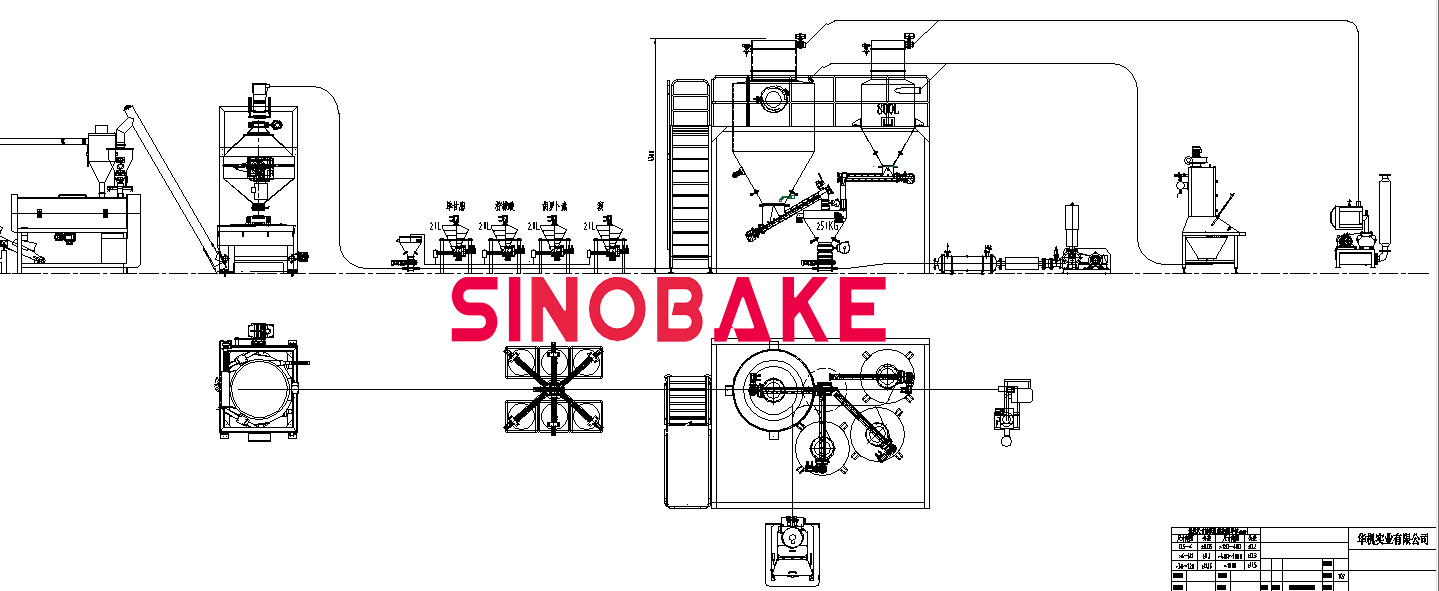

A whole potato chips production line consist of (for your reference)

| 1.Powder feeding lifting conveyor | 2.Dry material mixer |

| 3.Dry material lifting conveyor | 4.Upper storage conveyor |

| 5.Automatic quantitative feeding machine | 6.Quantitative conveying platform |

| 7.Wet material mixer | 8.Return air conveying system |

| 9.Wet material lifting conveyor | 10.Wet material unfolding conveyor |

| 11.Sheeting machine | 12.Rotary cutter machine |

| 13.Separating machine | 14.Dough scrap recycle conveyor |

| 15.Return breaking machine | 16.Water cooling machine |

| 17.Automatic water supply metering system | 18. Frying oven |

| 19.Heating system | 20.Oil storage tank |

| 21.Oil filter tank device | 22.Oil filter tank device |

| 23.Cooling conveyor | 24.Transition conveyor |

| 25.Viberating sprinkler |

production show

silo dosing system

Specification

| Material made of | 304 stainless steel,316 stainless steel |

| Bearing | NSK brand |

| Air cyclinder | YSC brand |

| Control | PLC Touch screen control |

| Raw material | Whole potato flour, potato flour, corn starch, tapioca flour |