+86 13794640490 info@sinobake.net

| Availability: | |

|---|---|

| Quantity: | |

HJ

SINOBAKE

8438100010

Product Description

SINOBAKE GROUP

Guangdong Shunde Huaji Industrial Co., Ltd. is a professional manufacturer of biscuits and cookies production line. We have been exporting our machines around the world to more than 100 countries. We operate the production in strict standards to provide reliable and safety products for customers all around the world.

We have employed professional technicians, employees who can provide an excellent service, and the right quality control equipment and personnel to do this job. The result of this being that we have passed the ISO9001: 2000 management system.

We invite you to discuss future opportunities with us, and to also take the opportunity yourself of putting to use our quality equipment.

SINOBAKE High Quality Advanced Knife Cut Cookie Production Line

Knife Cut Cookie

| The Complete Soft Biscuit production line consists of: | |

| 1. Dough Mixer | 2. Automatic Dough Tilting and Feeding System |

| 3. Knife Cut cookie machine | |

| 4. Tunnel Baking Oven | 5.Cooling Conveyor and Stacker |

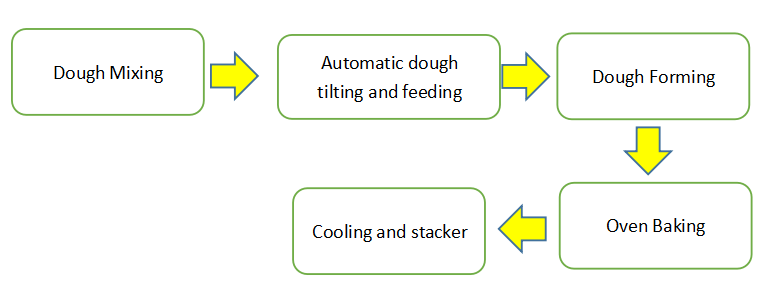

Biscuit Processing:

Vertical Planetary Mixer(300L)

Paddle form: vertical three oars | Mixing barrel type: removable dru |

| Motor and speed reducers : Europe brand | Bearing: Japan brand |

| Easy to control by PLC with touch screen | Control by PLC, |

Horizontal Dough Mixer (250KG/400KG/600KG/800KG for option)

| Horizontal single blade, Z shape,S shape | 304# Stainless steel outer cover and chromed sideboard |

| Motor and speed reducers : Europe brand | Bearing: Japan brand |

| Easy to control by PLC with touch screen | Control by PLC, |

Tilting Machine and Feeding system

| Europe brand motor & speed reducer | Chromed sideboard |

| SUS304 cover | Bearing: Japan brand |

| 304# stainless steel cover | Control by PLC |

Knife Cut Cookie Machine

Knife Cut Cookie Machine

Forming method: knife cutting; fastest working times: cutting 50 times/min | The side board is made of Q235 carbon steel, the thickness is 20mm after processing, and the surface is plated with hard chrome |

Roller diameter Ø165, surface treated with Teflon | The cutter cylinder uses Airtac brand |

This machine uses 1 set of servo, the servo motor uses Europe brand | Europe brand for main motor and reducer |

| Control appliances mainly use French brand | Bearings use Japan brand |

Tunnel Oven

| Electric Oven | Gas Oven |

| Diesel Oven | Direct Oven |

| Indirect Oven | Hybrid Oven |

Cooling conveyor and Stacker

| Imported PU belt, thickness 1.3mm | The cylinder uses Korean famous brand |

| All stainless steel for conveying racks and pallets | Europe brand for motor and reducer |

| Control appliances mainly use French brand | Bearings use Japan brand |

| Adopt no sanitary dead angle structure design, safe and sanitary | Install safety protection devices such as emergency stop switches |