+86 13794640490 info@sinobake.net

HJ600/800/1000/1200/1500/1800

SINOBAKE

8438100090

Product Description

The Cookie production line is an automated production equipment specially used to produce biscuits (cookies). This production line typically includes multiple process steps to ensure cookie production efficiency, quality and consistency.Adding different machines can add different flavors. The following are possible process steps for a general cookie production line:

Raw material preparation: Raw materials include flour, sugar, butter, eggs, etc. These ingredients may need to be mixed together and ensured in specific recipe proportions.

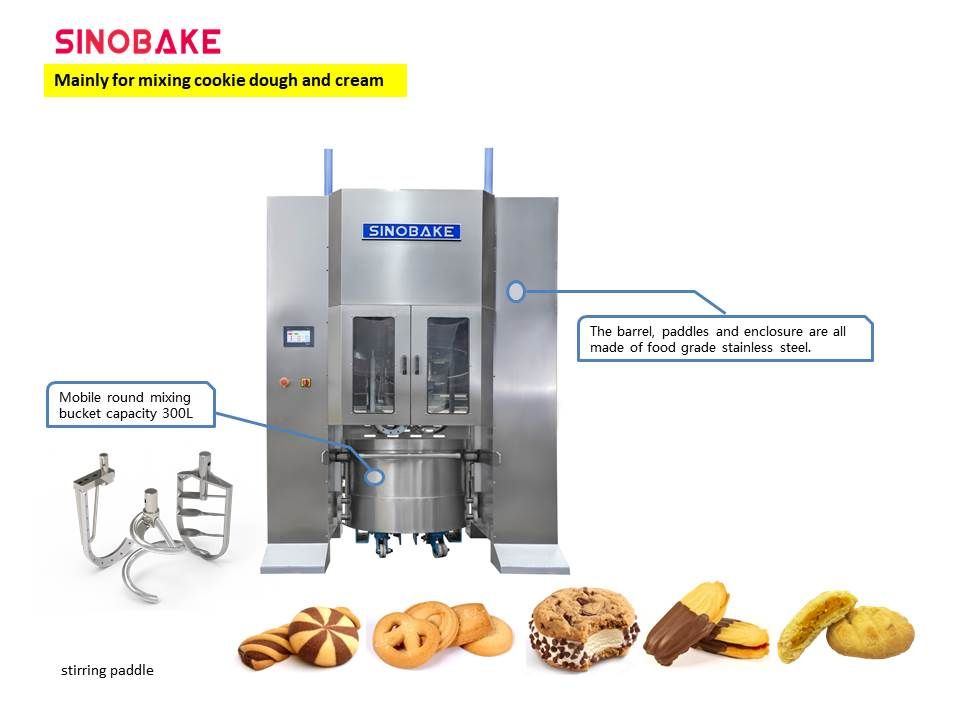

Mixing: Mixing equipment stirs and combines ingredients to form cookie dough. This process usually requires a certain amount of time and precise control to ensure uniformity of the dough.

Shaping: A cookie production line may include a molding equipment used to shape dough into specific shaped cookies. This can be done with equipment such as dies, cutters or extruders.

Baking: The cookies are placed in the oven for baking, ensuring they mature and rise at the proper temperature and time. The baking process has a significant impact on the taste and appearance of cookies.

Cooling: Baked cookies need to be cooled on a cooling rack in order to solidify and reach their final texture.

| Mode | Dimension(mm) | Weight(T) | NO.nozzles | Die Spacing |

| HJ600 | 2100*2000*2000 | 2.5T | 10 | 58.5 |

| HJ800 | 2100*2200*2000 | 3T | 12 | 60 |

| HJ1000 | 2100*2400*2000 | 3.5T | 16 | 60 |

| HJ1200 | 2100*2600*2000 | 4T | 20 | 58.5 |

Acompete cookie production line(for your reference)

| 1. Vertical Planetary Cookie Mixer The cookie and soft dough mixer is a dough mixer suitable for high-fat cookies and crispy biscuit dough. Also suitable for cream mixing |

| 2.Pouring Machine This machine is used to pour the dough mixed in the dough bucket into the storage hopper of the dough conveyor. |

| 3.Feeding conveyor This machine is used to cut the dough mixed by the dough mixer into small piece and convey them to the feeding machine. |

| 4.Cookie forming machine(multinational three color machine) Forming methods: twisting, stuffing, stripping, and cutting; Fastest working times: deposit: 35 times/min, stuffing: 50 times/min, strip cutting: 100/min, wire cutting: 100/min |

| 5.Molds The multifrop cookie machine can produce different shape cookies by changing molds |

| 6.Oil sprayer : This machine is used for high-speed atomized oil spraying on the upper and lower surfaces of baked biscuits. Improve the color, aroma and taste of biscuits. After oil spraying, the product will filter the oil and transport it. Send the machine to recycle excess oil. |

| 7.Enter oven mahcine This machine is used to transport the formed biscuits to the oven. |

| 8.Baking oven 1. This equipment is a baking equipment on the biscuit production line. It bakes biscuits and makes them delicious in color and flavor. |

| 9.Out of oven machine This machine is used to transport the baked biscuits out of the oven and achieve a flat transition of the biscuits. |

| 10.Cooling Conveyor This machine is used for normal cooling and conveying of biscuits; |

| 11.Star wheel stacker This machine is used for sorting biscuits before packaging to facilitate packaging. |