+86 13794640490 info@sinobake.net

| Availability: | |

|---|---|

| Quantity: | |

JX1000

SINOBAKE

8438100090

Product Description

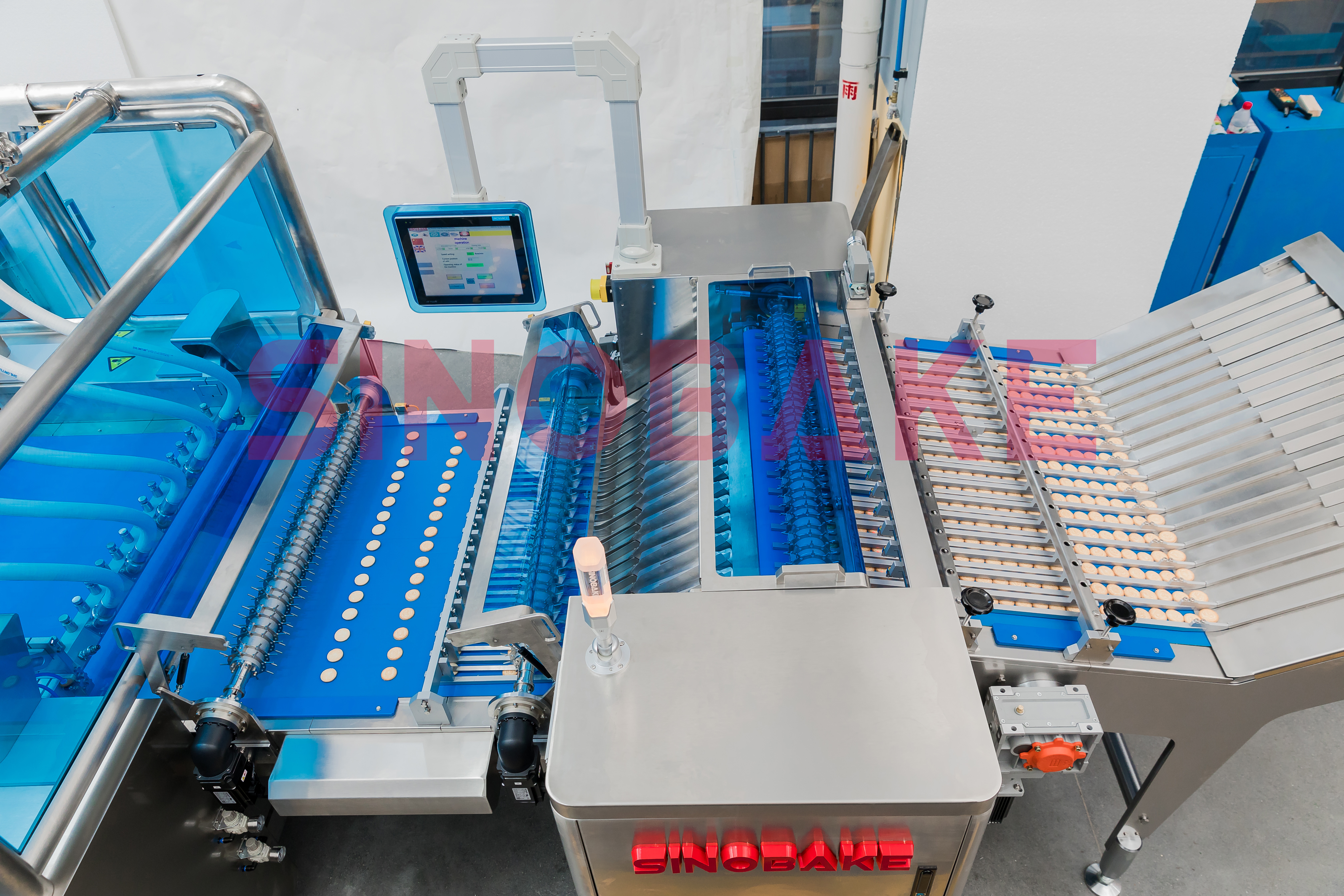

Cookie Capper consist of:

1.Automatic allocation of slide components

2.Sorting conveyor

3.Trim nail palladium assembly

4.Cookie front and back machine

5.Injection stackble conveyor

6.Injection system(singele lane)

7.Stackble system(singele lane)

1.Automatic allocation of slide components

1. Slideways: Divided according to product size requirements (prototype is 1 meter line Ø40 biscuit center 60 with 16 lanes)

2.Total motor power: 0.15KW

3. Dimensions (L*W*H): 765*1300*1450

4. Theoretical weight: about 0.5T

5.The slideways and skateboards are made of 304 material.

2.Sorting conveyor

1. Working width: 1000mm

2. Theoretical weight: about 0.8T

3. Dimensions (L*W*H): 1000*1400*1220

4. Working conveying speed: ≤60m/min

4. Power requirements: Determined according to customer needs (generally 380V/50Hz)

5. Main motor power: 1.5KW

3.Trim nail palladium assembly

1. Working width: 1000mm

2. The number of working paths: it depends on the size of the biscuits (the prototype can be arranged in 16 paths with Ø40 of 1 meter)

3. Working speed: ≤300r/min

2. Theoretical weight: about 0.2T

4.Cookie front and back machine

1. Working width: 1000mm

2. The number of working paths: it depends on the size of the biscuits (the prototype can be arranged in 16 paths with Ø40 of 1 meter)

3. Working speed: ≤300r/min

2. Theoretical weight: about 0.2T

4. Power requirements: Determined according to customer needs (generally 380V/50Hz)

5. Main motor power: 0.75KW

5.Injection and stackble conveyor

1.Main motor power: 1.5KW

2. Theoretical weight: about 1.0T

3. Dimensions (L*W*H): 3000*1400*900

4. Working conveying speed: ≤60m/min

5.Conveyor drive roller diameter: Ø160, the surface is covered with rubber, and the rubber material is non-toxic and oil-resistant material

6. SUS304 stainless steel side plate, support plate and outer cover

6.Injection system(singele lane)

1. Working head path: It depends on the size of the biscuit (16 heads can be arranged for a 1-meter noodle Ø40 of the prototype)

2. Theoretical weight: about 0.8T

3. Working speed: 50 times/minute

4. Concentration amount: 1-10g (reference value)

5. Cream delivery pressure: 1.0Mpa

6.Suitable for cream, diluted jam, chocolate,etc.

7.Stackble system(singele lane)

1. Working head path: It depends on the size of the biscuit (16 heads can be arranged for a 1-meter noodle Ø40 of the prototype)

2. Theoretical weight: about 0.8T

3. Working speed: 50 times/minute

4. Air consumption: 10 L/min

5. Air pressure: 0.6Mpa

6. Main motor power: 6.4KW

7.It is designed with no hygienic dead angle structure, which is safe, hygienic, easy to clean and disassemble

Simple design, easy maintenance and operation

8. Double-axis robotic hand structure, follow-up action design, flexible and easy operation

9. Connect with the manufacturer's feeding system

Contact Us For More Information