+86 13794640490 info@sinobake.net

HJ600/800/1000/1200/1500/1800

SINOBAKE

8438100090

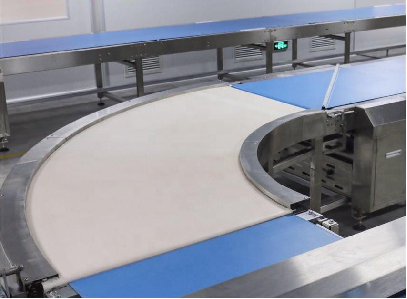

Cooling Conveyor:

A cooling conveyor in the food industry is a type of conveyor system specifically designed to cool down products as they move along the conveyor belt. This equipment is commonly used in food processing facilities to handle products that require a controlled cooling process after being subjected to heat treatment, such as cooking, baking, or other thermal processes.

Working width range 600mm to 1800mm.

Material standards:

1. The side plates are made of 304 stainless steel with a thickness of 10mm.

2. Conveyor rack plates, pallets, etc. are all made of stainless steel

3. The cover is made of SUS304 stainless steel (the cover door is painted with Q235 paint)

4. The circuit layout is neat and beautiful, and the wire trough is made of aluminum alloy (when equipped with a production line)

5. Motors and reducers use German brands: SEW/Siemens.

6. The control electrical appliances mainly use well-known brands: Schneider

7. The conveyor belt uses PU belts that meet food hygiene standards.

8. The surfaces of rollers, transition knives, etc. are all hard chromium plated.

9. The bearings use Japanese brand: NSK

10. The cylinder uses Korean famous brand YSC;

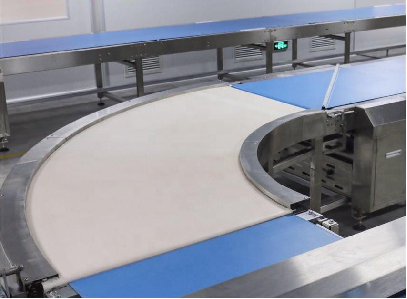

Cooling Conveyor:

A cooling conveyor in the food industry is a type of conveyor system specifically designed to cool down products as they move along the conveyor belt. This equipment is commonly used in food processing facilities to handle products that require a controlled cooling process after being subjected to heat treatment, such as cooking, baking, or other thermal processes.

Working width range 600mm to 1800mm.

Material standards:

1. The side plates are made of 304 stainless steel with a thickness of 10mm.

2. Conveyor rack plates, pallets, etc. are all made of stainless steel

3. The cover is made of SUS304 stainless steel (the cover door is painted with Q235 paint)

4. The circuit layout is neat and beautiful, and the wire trough is made of aluminum alloy (when equipped with a production line)

5. Motors and reducers use German brands: SEW/Siemens.

6. The control electrical appliances mainly use well-known brands: Schneider

7. The conveyor belt uses PU belts that meet food hygiene standards.

8. The surfaces of rollers, transition knives, etc. are all hard chromium plated.

9. The bearings use Japanese brand: NSK

10. The cylinder uses Korean famous brand YSC;