+86 13794640490 info@sinobake.net

| Availability: | |

|---|---|

| Quantity: | |

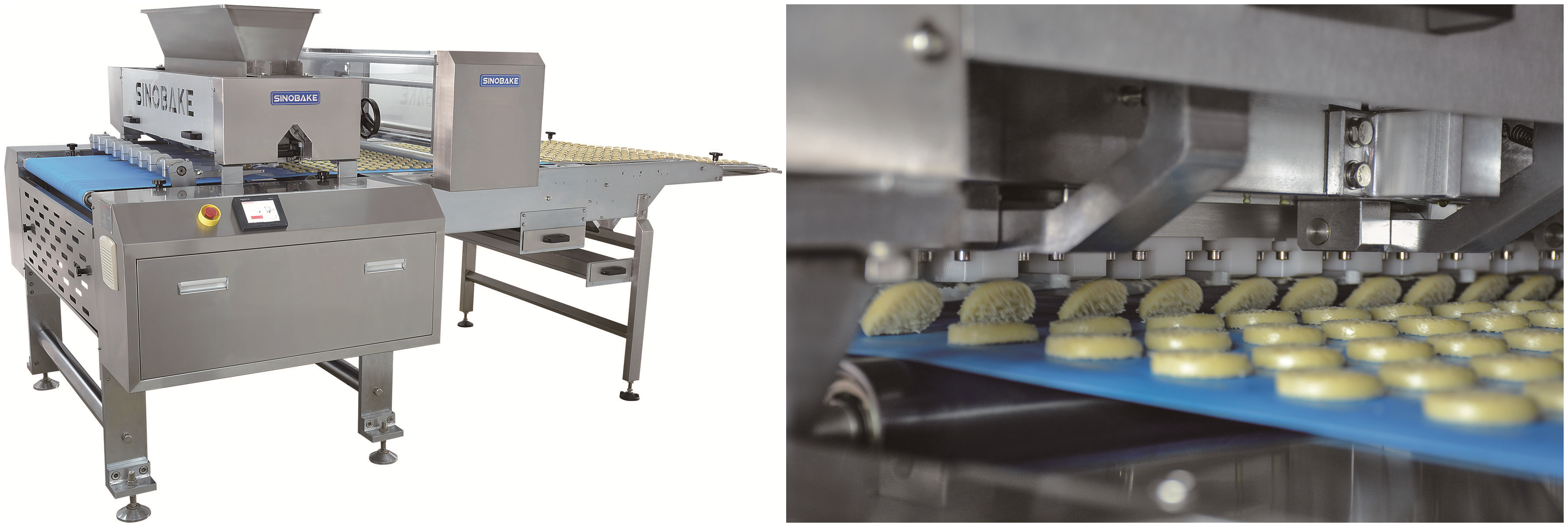

CK1C

SINOBAKE

8438100090

One color wire cut cookie machine

Features:

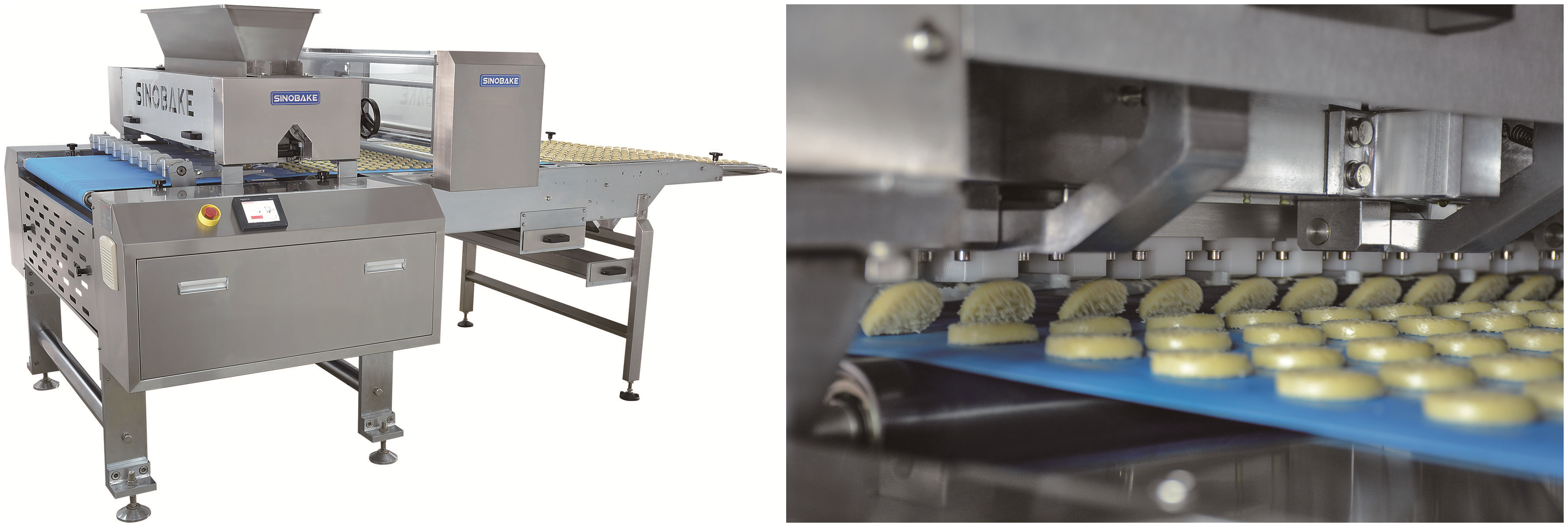

This machine is mainly used for the forming of high-fat cookies and cakes.

| Model | 600 | 800 | 1000 | 1200 |

| Dimension(L*W*H)MM | 2100*2000*1850 | 2100*2200*1850 | 2100*2400*1850 | 2100*2600*1850 |

| Weigth(T) | 1.5 | 1.9 | 2.2 | 2.5 |

| Total power(KW) | 6-12.5KW | 6-12.5KW | 6-12.5KW | 6-12.5KW |

Parameters:

1. Forming method: wire cutting; fastest working times: cutting 100 times/min

2. Biscuit weight deviation: ±4% (each 5 biscuit weighing); pass rate: 98%

3. Production speed: Determined according to the furnace length and baking time of the production line

4. Energy requirements: Determined according to customer needs (generally 380V/50Hz), total power: about 4KW

5.Feeding by a feed pump, precise control, small deviation of biscuit weight;

6.The feeding trough roller, feed pump and cutting are driven by servo motors, which are controlled independently

7. The parameters such as the speed of the grooved roller, the feeding speed of the material pump and the cutting speed are controlled by the touch screen, which is easy to operate

8. The material pump assembly adopts the worm gear clamping method, which is convenient for disassembly, cleaning and replacement, and simple operation.

Two color wire cut cookie machine

| Model | 600 | 800 | 1000 | 1200 |

| Dimension(L*W*H)MM | 2100*2000*1850 | 2100*2200*1850 | 2100*2400*1850 | 2100*2600*1850 |

| Weight(T) | 2 | 2.5 | 3 | 3.5 |

| Total power (KW) | 10-21kw | 10-21kw | 10-21kw | 10-21kw |

1. Forming method: double row direct extrusion or rotary extrusion, single row direct extrusion or rotary extrusion

2. Fastest working times: twisting 55 times/min cutting times: 100 times/min pulling and cutting: 100 times/min

3. Cake weight deviation: extruded cake ±4% (weigh every 5 cakes);

4. Production speed: determined according to the furnace length and baking time of the production line

One color wire cut cookie machine

Features:

This machine is mainly used for the forming of high-fat cookies and cakes.

| Model | 600 | 800 | 1000 | 1200 |

| Dimension(L*W*H)MM | 2100*2000*1850 | 2100*2200*1850 | 2100*2400*1850 | 2100*2600*1850 |

| Weigth(T) | 1.5 | 1.9 | 2.2 | 2.5 |

| Total power(KW) | 6-12.5KW | 6-12.5KW | 6-12.5KW | 6-12.5KW |

Parameters:

1. Forming method: wire cutting; fastest working times: cutting 100 times/min

2. Biscuit weight deviation: ±4% (each 5 biscuit weighing); pass rate: 98%

3. Production speed: Determined according to the furnace length and baking time of the production line

4. Energy requirements: Determined according to customer needs (generally 380V/50Hz), total power: about 4KW

5.Feeding by a feed pump, precise control, small deviation of biscuit weight;

6.The feeding trough roller, feed pump and cutting are driven by servo motors, which are controlled independently

7. The parameters such as the speed of the grooved roller, the feeding speed of the material pump and the cutting speed are controlled by the touch screen, which is easy to operate

8. The material pump assembly adopts the worm gear clamping method, which is convenient for disassembly, cleaning and replacement, and simple operation.

Two color wire cut cookie machine

| Model | 600 | 800 | 1000 | 1200 |

| Dimension(L*W*H)MM | 2100*2000*1850 | 2100*2200*1850 | 2100*2400*1850 | 2100*2600*1850 |

| Weight(T) | 2 | 2.5 | 3 | 3.5 |

| Total power (KW) | 10-21kw | 10-21kw | 10-21kw | 10-21kw |

1. Forming method: double row direct extrusion or rotary extrusion, single row direct extrusion or rotary extrusion

2. Fastest working times: twisting 55 times/min cutting times: 100 times/min pulling and cutting: 100 times/min

3. Cake weight deviation: extruded cake ±4% (weigh every 5 cakes);

4. Production speed: determined according to the furnace length and baking time of the production line