+86 13794640490 info@sinobake.net

| Availability: | |

|---|---|

| Quantity: | |

HJ600/800/1000/1200/1500/1800

SINOBAKE

8438100090

Product Description

A dry pet food making machine production line is a specialized manufacturing system used to produce dry pet food products such as kibble for dogs and cats. This production line typically involves a series of machines and processes designed to mix, extrude, dry, and package pet food in a continuous and automated fashion. Here are the key components and processes involved in a typical dry pet food production line:

Raw Material Handling: The process begins with the handling of raw ingredients. This includes storing, measuring, and mixing various ingredients like meat meal, grains, vitamins, minerals, and additives. Precise control of ingredient ratios is crucial for maintaining product consistency.

Grinding and Mixing: In some cases, raw ingredients are ground to achieve a consistent particle size. Mixing equipment is used to blend all ingredients thoroughly to create a uniform mixture.

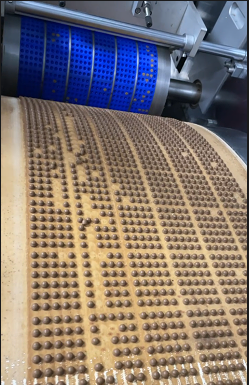

Pet food forming : The mixed ingredients are then fed into an rotary moulder. An Rotary moulder is a machine that uses heat, pressure, and mechanical action to cook the mixture and create a dough-like consistency. This dough is then forced through a die with specific shapes to produce kibble of the desired size and shape. Customized different pet food shape mold.

Rotary moulder

Pet food forming

Pet food forming

Drying: The extruded kibble passes through a drying process to reduce its moisture content to the desired level. This is typically done using conveyor belt dryers or similar equipment.

Cooling: After drying, the pet food is cooled to room temperature to prevent moisture reabsorption and to prepare it for packaging.

Quality Control: Throughout the production line, quality control measures are in place to monitor parameters such as moisture content, temperature, and kibble size. Any substandard products are typically removed from the production line.

Cleaning and Maintenance: Regular cleaning and maintenance of the machinery are essential to ensure product quality and the longevity of the production line.

It's important to note that the specific design and configuration of a dry pet food making machine production line can vary based on the scale of production, the types of pet food being manufactured, and the level of automation.